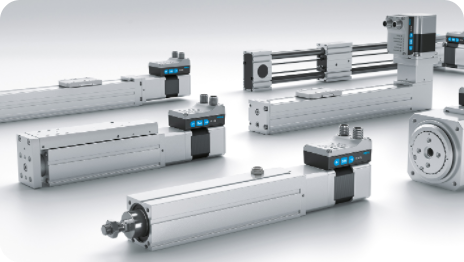

1. Linear motion systems are critical in precision applications where controlled movement is required. Due to aluminum's low density, structures built from aluminum profiles are easier to move and require less energy, making the systems more efficient. The strength-to-weight ratio of aluminum is one of the key considerations here, as it enables the design of robust yet lightweight machinery, reducing wear on moving parts and extending the equipment's life

2. In conveyor systems, aluminum serves as an excellent material frames and tracks. These systems are ubiquitous in packaging, manufacturing, and assembly lines where products or materials need to be moved seamlessly throughout the process. Aluminum's corrosion resistance is a significant advantage, ensuring longevity even in environments where the material may be exposed to harsh substances or temperature variations.

3. Automated machinery benefits from aluminum in multipleways. In robotics, lightweight aluminum components increase the speed and reduce the power consumption of robotic arms. For packaging and 3D printing equipment, aluminum parts help achieve high precision due to their dimensional stability.

4. Aluminum also plays a pivotal role in the production of linear guides. These guides are the backbone of many machines offering precise motion control, crucial in fields such as medical equipment, aerospace, and semiconductor manufacturing. Aluminum's natural low frictive properties contribute to a smoother glide of components, reducing the need for extensive lubrication and maintenance.

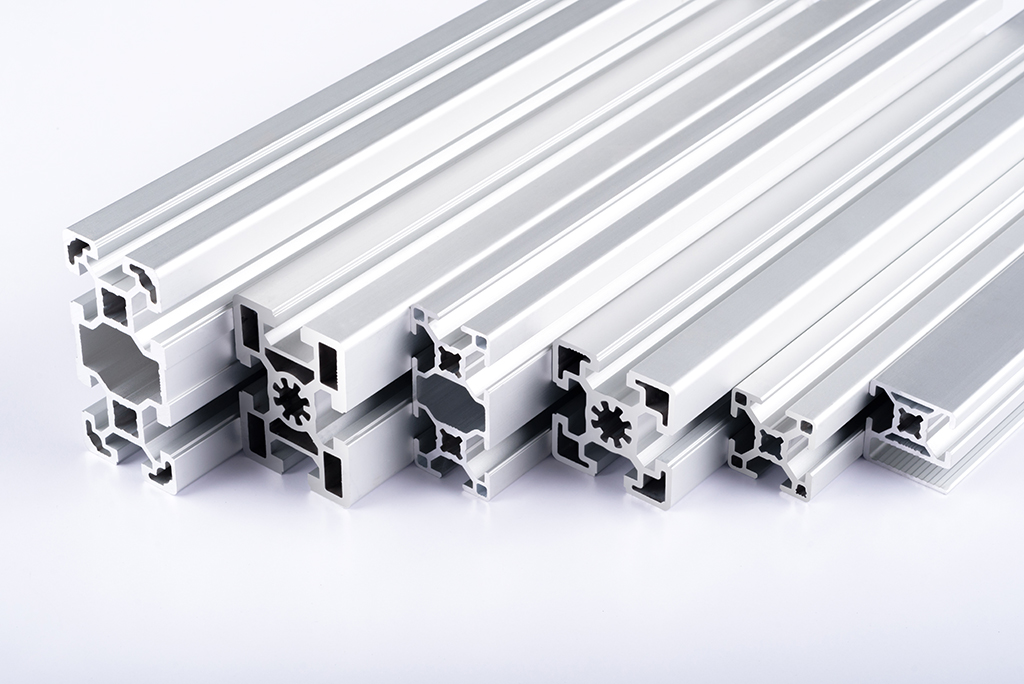

5. In the case of equipment such as 3D printers, CNC machines, and laser cutting devices, aluminum’s machinability allows for easy customization and adaptability. Custom aluminum extrusions can be manufactured to accommodate unique dimensions and profiles required by specific applications.