Enamelled wire

| Wire with enamel insulation based on modified polyester |

|

Wire insulation is resistant:

|

| PET |

| round wires |

| Ø-0,90 |

| Ø-0,95 |

| Ø-1,00 |

| Ø-1,06 |

| Ø-1,12 |

| Ø-1,18 |

| Ø-1,25 |

| Ø-1,32 |

| Ø-1,4 |

| Ø-1,45 |

| Ø-1,5 |

| Ø-1,56 |

| Ø-1,6 |

| Ø-1,7 |

| Ø-1,75 |

| Ø-1,8 |

| Ø-1,9 |

| Ø-2,0 |

| Ø-2,12 |

| Ø-2,24 |

| Ø-2,36 |

| Ø-2,5 |

Copper bus bars

| Alloy | Composition* % | EN - CEN/TS 13388:2008 | ASTM/USA |

|---|---|---|---|

| Cu-OF | Cu + Ag min. 99,95 % | Cu-OF / CW008A | C10200 |

| * Other elements max %: O 0,0010,Bi 0,0005, Pb 0,005 |

| Soft temper | Half-hard temper | Hard temper | |

|---|---|---|---|

| Hardness HV | 35 - 65 HV | 70 - 95 HV | 85 - 115 HV |

| Tensile strength | 200 - 220 N/mm2 | 250 - 350 N/mm2 | 260 - 400 N/mm2 |

| 0,2% yield strength | 35 - 65 N/mm2 | 180 - 280 N/mm2 | 220 - 380 N/mm2 |

| Elongation | min. 40 % | min. 12 % | min. 5 % |

| Size | a (mm) | b (mm) | WEIGHT (kg/m) |

|---|---|---|---|

| 2.5х12.5 | 12.5 | 712.5 | 1.391 |

| 15х6 | 6 | 15 | 0.801 |

| 20х3 | 3 | 20 | 0.534 |

| 20х4 | 4 | 20 | 0.712 |

| 20х5 | 5 | 20 | 0.890 |

| 20х8 | 8 | 20 | 1.424 |

| 20x10 | 10 | 20 | 1,782 |

| 30x8 | 8 | 30 | 2,136 |

| 30х10 | 10 | 30 | 2.670 |

| 30х20 | 20 | 30 | 5.340 |

| 40х3 | 3 | 40 | 1.068 |

| 40x4 | 4 | 40 | 1,424 |

| 40х4.5 | 4.5 | 40 | 1.602 |

| 40x5 | 5 | 40 | 1,780 |

| 40xR5 | 5 | 40 | 1,780 |

| 40х6 | 6 | 40 | 2.136 |

| 40x8 | 8 | 40 | 2,849 |

| 40x10 | 10 | 40 | 3,560 |

| 40х20 | 20 | 40 | 7.120 |

| 40x40 | 40 | 40 | 14,256 |

| 50x3 | 3 | 50 | 1.335 |

| 50x4 | 4 | 50 | 1,782 |

| 50x5 | 5 | 50 | 2,225 |

| 50xR5 | 5 | 50 | 2,225 |

| 50x6 | 6 | 50 | 2,670 |

| 50х8 | 8 | 50 | 3.560 |

| 50x10 | 10 | 50 | 4,450 |

| 60x4 | 4 | 60 | 2.136 |

| 60х5 | 5 | 60 | 2.670 |

| 60x6 | 6 | 60 | 3,204 |

| 60x8 | 8 | 60 | 4,272 |

| 60x10 | 10 | 60 | 5,340 |

| 60x12 | 12 | 60 | 6,415 |

| 60x16 | 16 | 60 | 8.544 |

| 65х4 | 4 | 65 | 2.314 |

| 70x4 | 4 | 70 | 2,495 |

| 70x5 | 5 | 70 | 3,115 |

| 70х10 | 10 | 70 | 6.230 |

| 80x5 | 5 | 80 | 3,564 |

| 80x8 | 8 | 80 | 5,696 |

| 80x10 | 10 | 80 | 7,120 |

| 80x15 | 15 | 80 | 10,692 |

| 80x20 | 20 | 80 | 14.240 |

| 90x10 | 10 | 90 | 8,010 |

| 100x10 | 10 | 100 | 8.900 |

| 100x12 | 12 | 100 | 10,692 |

| 120х10 | 10 | 120 | 10.680 |

| 120х12 | 12 | 120 | 12.816 |

| 120х20 | 20 | 120 | 21.360 |

| 140х15 | 15 | 140 | 18.690 |

| 150х10 | 10 | 150 | 13.350 |

| 160x10 | 10 | 160 | 14,256 |

| 160х15 | 15 | 160 | 21.360 |

| 140х15 | 15 | 140 | 18.690 |

| 150х10 | 10 | 150 | 13.350 |

| 160x10 | 10 | 160 | 14,256 |

| 160х15 | 15 | 160 | 21.360 |

Copper straight cut pipes

| Copper brand: | М1 М00K |

| Standards: | EN 12735-1; EN 1057; ASTM B68; ASTM B280 |

| Tempers: | Hard, half hard, soft |

| Packaging: | In straight cuts from up to 6 m (in bundles up to 350 kg and in wooden boxes up to 1 ton) |

| Copper pipes in straight length are used in many areas of industry, including refrigeration, air conditioning systems, and heat exchange units. They meet the requirements of international standards ASTM B280, ASTM B68. | |

| DIAMETER | WALL THICKNESS | ||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | |||||||||||||||||||||||||||||||||

| 0,28 | 0,30 | 0,32 | 0,35 | 0,40 | 0,45 | 0,50 | 0,60 | 0,70 | 0,80 | 0,90 | 1,00 | 1,10 | 1,20 | 1,25 | 1,30 | 1,35 | 1,50 | 1,70 | 1,80 | 1,90 | 2,00 | ||||||||||||

| inch | |||||||||||||||||||||||||||||||||

| inch | mm | ||||||||||||||||||||||||||||||||

| 0,011 | 0,012 | 0,013 | 0,014 | 0,016 | 0,018 | 0,020 | 0,024 | 0,028 | 0,031 | 0,035 | 0,039 | 0,043 | 0,047 | 0,047 | 0,051 | 0,053 | 0,059 | 0,067 | 0,071 | 0,075 | 0,079 | PACKING FORM | LENGTH | ||||||||||

| 4 |  |

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||||||||||

| 3/16 | 4,76 |  |

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||||

| 5 |  |

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||||||||||

| 5,5 |  |

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||||||||

| 6 |  |

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||||||||

| 1,4 | 6,35 |  |

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||

| 5/16 | 7,39 |  |

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||

| 7,8 |  |

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||||||

| 8 |  |

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||

| 9 |  |

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||||||||

| 3/8 | 9/52 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||

| 9,8 |  |

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||||||||

| 10 |  |

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||||||

| 12 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||

| 12,5 |  |

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||||

| 1/2 | 12,7 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||

| 13 |  |

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||

| 13,5 |  |

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||||

| 14 |  |

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||

| 5/8 | 15,87 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||

| 16 |  |

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||

| 16,5 |  |

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||||

| 18 |  |

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||

| 3/4 | 19,05 |  |

|

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||

| 19,5 |  |

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||

| 20 |  |

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||

| 22 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||

| 7/8 | 22,22 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||

| 25 |  |

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||

| 1 | 25,4 |  |

|

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||

| 25,5 |  |

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||||

| 28 |  |

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||

| 1 1/8 | 28,57 |  |

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||

| 29 |  |

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||

| 2 3/16 | 30 |  |

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||

| 31 |  |

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||||||||

| 1 17/64 | 32 |  |

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||||||||||

| 34 |  |

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||||||

| 1 3/8 | 34,92 |  |

|

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||

| 1 3/8 | 35 |  |

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||

| 38 |  |

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||||

| 1 37/64 | 40 |  |

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | ||||||||||||||||||||

| 1 5/8 | 41,27 |  |

|

|

|

|

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||

| 1 21/32 | 42 |  |

|

|

|

|

|

|

|

|

STRAIGHT LENGTH | from 3 to 6 m | |||||||||||||||||||||

Brazing alloy

| BCu94P6 | is a zero-silver copper-phosphorus solder, a two-component solder used to brazing alloy. |

| BCu92P6Ag | solder, in which silver contains no more than 2%. This material is used for soldering copper and copper alloys, suitable for elements that are protected from shock and vibration. |

| BCu89P6Ag5 | a product with a silver content of up to 5%. It is a plastic material that spreads slowly over the surface and ills large gaps well. The material performs well with temperature fluctuations. |

| BCu805P5Ag15 | material with this marking contains 15% silver, it is plastic, perfectly ills all cracks and gaps, and forms strong and tight seams. |

| BCu65P5Ag30 | solder with a silver content up to 30%. Seams obtained by soldering with such solder are strong and resistant to corrosion. |

| NAME OF PRODUCT | DESIGNATION | MELTING | WORKING | SCOPE OF APPLICATION | DENSITY G / CM 3 | PROCESSING QUALITY | DIN EN 1044/DIN 8513 ISO 3677 |

|---|---|---|---|---|---|---|---|

| Brazing alloy 0,5% (lat, round) diameter 2mm to 3,5mm, length 500mm |

The material used in soldering for joining |

715-805  C C |

760 |

Air conditioning, refrigeration |

9,2-7,35 | good | DIN EN 1044 |

| Brazing alloy 0,5% (lat, round) diameter 2mm to 3,5mm, length 500mm | 660-830  C C |

750 | 9,2-7,35 | good | DIN EN 1045 | ||

| Brazing alloy 1,8% (lat, round) diameter 2mm to 3,5mm, length 500mm BCUP | 655-825  C C |

745 | 9,2-7,35 | good | DIN EN 1046 | ||

| Brazing alloy 2% (lat, round) diameter 2mm to 3,5mm, length 500mm | 650-820  C C |

740 | 9,2-7,35 | good | DIN EN 1047 | ||

| Brazing alloy 5% (lat, round) diameter 2mm to 3,5mm, length 500mm | 650-800  C C |

710 | 9,2-7,35 | good | DIN EN 1048 | ||

| Brazing alloy 15% (lat, round) diameter 2mm to 3,5mm, length 500mm | 620-780  C C |

680 | 9,2-7,35 | good | DIN EN 1049 | ||

| Brazing alloy 30% (lat, round) diameter 2mm to 3,5mm, length 500mm | 600-750  C C |

650 | 9,2-7,35 | good | DIN EN 1050 |

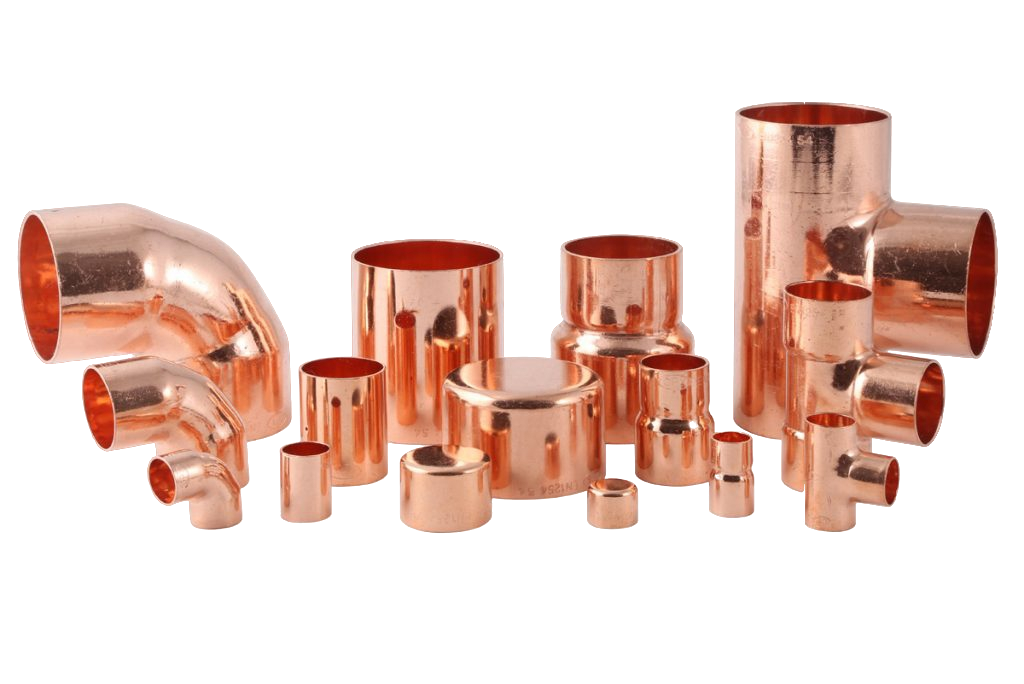

Fittings

|

|

||

|---|---|---|---|

| Model | Аrticles | Metric size | Weight(g) |

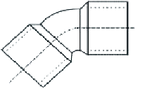

| Two-socket bend 45 | |||

| 5001А | 22 | 26.86 | |

| 5001А | 28 | 50 | |

| 5001А | 35 | 100 | |

| 5001А | 42 | 120 | |

|

||||

|---|---|---|---|---|

|

|

|||

| Model | Аrticles | Metric size | Weight(g) | |

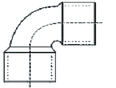

| Two-socket elbow 90 g short | ||||

| 5090А | 8 | 5/16 | 6 | |

| 5090А | 10 | 3/8 | 5.6 | |

| 5090А | 12 | 1/2 | 8.05 | |

| 5090А | 15 | 13.63 | ||

| 5090А | 16 | 5/8 | 16.53 | |

| 5090А | 18 | 25.29 | ||

| 5090А | 19 | 3/4 | 25.5 | |

| 5090А | 22 | 7/8 | 32.18 | |

| 5090А | 28 | 11/8 | 54.61 | |

| 5090А | 35 | 13/8 | 109.1 | |

| 5090А | 42 | 15/8 | 140.1 | |

|

|

||

|---|---|---|---|

| Model | Аrticles | Metric size | Weight(g) |

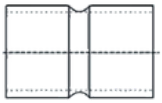

| Coupling | |||

| 5270 | 8 | 4.1 | |

| 5270 | 10 | 5.55 | |

| 5270 | 12 | 6.2 | |

| 5270 | 15 | 7.8 | |

| 5270 | 18 | 12.6 | |

| 5270 | 22 | 35.4 | |

| 5270 | 28 | 35.4 | |

| 5270 | 35 | 61.3 | |

| 5270 | 42 | 92.7 | |

|

|

|||

|---|---|---|---|---|

| Model | Аrticles | Metric size | Weight(g) | |

| Two-pipe elbow 90 gr long | ||||

| 5002А | 8 | 5/16 | 5.6 | |

| 5002А | 10 | 3/8 | 8.17 | |

| 5002А | 12 | 1/2 | 10.87 | |

| 5002А | 15 | 19.16 | ||

| 5002А | 16 | 5/8 | 23.5 | |

| 5002А | 18 | 3/4 | 32.86 | |

| 5002А | 19 | 3/4 | 35.11 | |

| 5002А | 22 | 7/8 | 45.94 | |

| 5002А | 28 | 11/8 | 83.28 | |

| 5002А | 35 | 13/8 | 152.2 | |

| 5002А | 42 | 15/8 | 226 | |

|

|

||

|---|---|---|---|

| Model | Аrticles | Metric size | Weight(g) |

| Coupling | |||

| 5301 | 8 | ||

| 5301 | 10 | 4 | |

| 5301 | 12 | 4 | |

| 5301 | 15 | 5 | |

| 5301 | 18 | 11 | |

| 5301 | 22 | 13 | |

| 5301 | 22 | 24 | |

| 5301 | 35 | 43 | |

| 5301 | 42 | 72 | |

|

|

||

|---|---|---|---|

| Model | Аrticles | Metric size | Weight(g) |

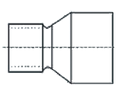

| Reducing coupling | |||

| 5240 | 15*10 | 9.65 | |

| 5240 | 15*12 | 9.4 | |

| 5240 | 15*12 | 13 | |

| 5240 | 15*15 | 13.5 | |

| 5240 | 15*12 | 21.2 | |

| 5240 | 15*15 | 21.1 | |

| 5240 | 15*18 | 21.6 | |

| 5240 | 15*15 | 31.7 | |

| 5240 | 15*18 | 31.5 | |

| 5240 | 15*22 | 36.3 | |

| 5240 | 15*22 | 63.2 | |

| 5240 | 15*28 | 61.4 | |

| 5240 | 15*22 | 94.5 | |

| 5240 | 15*28 | 94.3 | |

| 5240 | 15*35 | 96.7 | |

|

|

|||

|---|---|---|---|---|

| Model | Аrticles | Metric size | Weight(g) | |

| Tee | ||||

| 5130 | 6 | 4.06 | ||

| 5130 | 8 | 5/16 | 7.4 | |

| 5130 | 10 | 3/8 | 11.4 | |

| 5130 | 12 | 1/2 | 15.86 | |

| 5130 | 15 | 28.5 | ||

| 5130 | 16 | 5/8 | 31.2 | |

| 5130 | 18 | 51.15 | ||

| 5130 | 19 | 3/4 | 53.45 | |

| 5130 | 22 | 7/8 | 64.23 | |

| 5130 | 28 | 11/8 | 102.82 | |

| 5130 | 35 | 13/8 | 166 | |

| 5130 | 42 | 14/8 | 265 | |

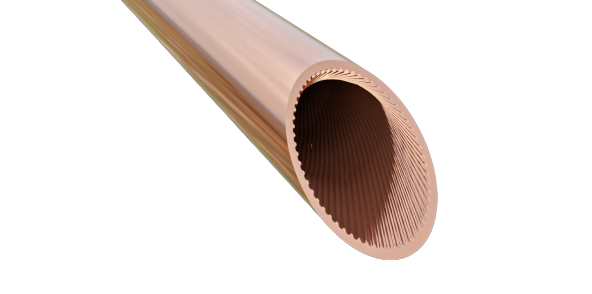

Inner grooved tubes

| Copper brand: | М1 М00K |

| Standards: | EN 12735-1; EN 1057; ASTM B68; ASTM B280 |

| Tempers: | Hard, half hard, soft |

| Packaging: | In LWC from 100 kg to 150 kg |

| COPPER PIPE FOR REFRIGERATION EQUIPMENT is produced according to B 280 (ASTM) and EN 12735-1 (EU) standards. These standards regulate diameter sizes, wall thickness, maximum operating pressure, and many different seamless copper pipes. These characteristics are necessary to produce optimal copper tubes for long and efficient operation in refrigeration equipment. Material composition: Cu (copper) - 99.9%, P (phosphorus) - 0.03%. It is these pipes that will have such properties as durability, vibration resistance, corrosion resistance, and high thermal conductivity. No less important quality in standards for copper pipes is resistance to freons, pressure, and temperatures. Important, that due to the high ductility of copper, when working fluids freeze, the pipe is deformed, but does not rupture. | |

| DIAMETER | WALL THICKNESS | RIB HEIGHT | QUAN-TY OF RIBS | PACKING | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | |||||||||||||||||||||||||||

| 0,25 | 0,28 | 0,30 | 0,32 | 0,35 | 0,38 | 0,40 | 0,42 | 0,45 | 0,50 | 0,55 | 0,60 | ||||||||||||||||

| inch | |||||||||||||||||||||||||||

| inch | mm | ||||||||||||||||||||||||||

| 0,010 | 0,011 | 0,012 | 0,013 | 0,014 | 0,015 | 0,016 | 0,017 | 0,018 | 0,020 | 0,023 | 0,024 | ||||||||||||||||

| 5 |  |

|

0,15±0,01 | 40 | LWC | ||||||||||||||||||||||

| 3/5 | 7 |  |

|

|

|

0,18±0,02 | 44 | LWC | |||||||||||||||||||

| 3/8 | 7.93 |  |

|

|

|

0,15±0,02 | 50 | LWC | |||||||||||||||||||

| 3/9 | 9.52 |  |

|

|

|

|

|

|

|

0,16±0,03 | 50 | LWC | |||||||||||||||

| 3/11 | 12 |  |

|

|

|

0,16±0,05 | 60 | LWC | |||||||||||||||||||

| 3/12 | 12,7 |  |

|

|

|

0,25±0,06 | 60 | LWC | |||||||||||||||||||

| 3/13 | 15,87 |  |

|

|

|

|

|

0,25±0,05 | 65 | LWC | |||||||||||||||||

Lwc

| Copper brand: | М1 М00K |

| Standards: | EN 12735-1; EN 1057; ASTM B68; ASTM B280 |

| Tempers: | Hard, half hard, soft |

| Packaging: | In coils from 100 kg to 300 kg |

| Copper pipes in straight length are used in many areas of industry, including refrigeration, air conditioning systems, and heat exchange units. They meet the requirements of international standards ASTM B280, ASTM B68. | |

| DIAMETER | WALL THICKNESS | PACKING | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | |||||||||||||||||||||||||||||

| 0,28 | 0,30 | 0,32 | 0,35 | 0,40 | 0,45 | 0,50 | 0,60 | 0,70 | 0,80 | 0,90 | 1,00 | 1,10 | 1,20 | 1,25 | 1,30 | 1,35 | 1,50 | 1,70 | 1,80 | 1,90 | 2,00 | ||||||||

| inch | |||||||||||||||||||||||||||||

| inch | mm | ||||||||||||||||||||||||||||

| 0,011 | 0,012 | 0,013 | 0,014 | 0,016 | 0,018 | 0,020 | 0,024 | 0,028 | 0,031 | 0,035 | 0,039 | 0,043 | 0,047 | 0,047 | 0,051 | 0,053 | 0,059 | 0,067 | 0,071 | 0,075 | 0,079 | ||||||||

| 4 |  |

|

|

LWC | |||||||||||||||||||||||||

| 3/16 | 4,76 |  |

|

|

|

|

|

|

|

LWC | |||||||||||||||||||

| 5 |  |

|

|

|

LWC | ||||||||||||||||||||||||

| 5,5 |  |

|

|

|

|

LWC | |||||||||||||||||||||||

| 6 |  |

|

|

|

|

|

LWC | ||||||||||||||||||||||

| 1,4 | 6,35 |  |

|

|

|

|

|

|

|

|

|

LWC | |||||||||||||||||

| 5/16 | 7,39 |  |

|

|

|

|

|

|

|

|

|

|

LWC | ||||||||||||||||

| 7,8 |  |

|

|

|

|

|

|

LWC | |||||||||||||||||||||

| 8 |  |

|

|

|

|

|

|

|

|

|

|

LWC | |||||||||||||||||

| 9 |  |

|

|

|

|

|

LWC | ||||||||||||||||||||||

| 3/8 | 9/52 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LWC | ||||||||||||

| 9,8 |  |

|

|

|

|

LWC | |||||||||||||||||||||||

| 10 |  |

|

|

|

|

|

|

|

LWC | ||||||||||||||||||||

| 12 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LWC | |||||||||||||

| 12,5 |  |

|

|

|

|

|

|

|

|

LWC | |||||||||||||||||||

| 1/2 | 12,7 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LWC | |||||||||||

| 13 |  |

|

|

|

|

|

|

|

|

|

|

|

LWC | ||||||||||||||||

| 13,5 |  |

|

|

|

|

|

|

|

|

|

LWC | ||||||||||||||||||

| 14 |  |

|

|

|

|

|

|

|

|

|

|

|

LWC | ||||||||||||||||

| 5/8 | 15,87 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

LWC | |||||||||||||

| 16 |  |

|

|

|

|

|

|

|

|

|

|

|

LWC | ||||||||||||||||

| 16,5 |  |

|

|

|

|

|

|

|

|

LWC | |||||||||||||||||||

| 18 |  |

|

|

|

|

|

|

|

|

|

|

|

LWC | ||||||||||||||||

| 3/4 | 19,05 |  |

|

|

|

|

|

|

|

|

|

|

|

|

LWC | ||||||||||||||

| 19,5 |  |

|

|

|

|

|

|

|

|

|

|

LWC | |||||||||||||||||

| 20 |  |

|

|

|

|

|

|

|

|

|

|

LWC | |||||||||||||||||

Pancake coil

| Copper brand: | М1 М00K |

| Standards: | EN 12735-1; EN 1057; ASTM B68; ASTM B280 |

| Tempers: | Hard, half hard, soft |

| Packaging: | PC 15m, 25m, 30m, 50m (in carton boxes) Material: Cu-DHP |

| DIAMETER | WALL THICKNESS | PACKING | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | |||||||||||||||||||||||||||||

| 0,28 | 0,30 | 0,32 | 0,35 | 0,40 | 0,45 | 0,50 | 0,60 | 0,70 | 0,80 | 0,90 | 1,00 | 1,10 | 1,20 | 1,25 | 1,30 | 1,35 | 1,50 | 1,70 | 1,80 | 1,90 | 2,00 | ||||||||

| inch | |||||||||||||||||||||||||||||

| inch | mm | ||||||||||||||||||||||||||||

| 0,011 | 0,012 | 0,013 | 0,014 | 0,016 | 0,018 | 0,020 | 0,024 | 0,028 | 0,031 | 0,035 | 0,039 | 0,043 | 0,047 | 0,047 | 0,051 | 0,053 | 0,059 | 0,067 | 0,071 | 0,075 | 0,079 | ||||||||

| 4 |  |

|

|

PANCAKE COIL | |||||||||||||||||||||||||

| 3/16 | 4,76 |  |

|

|

|

|

|

|

|

PANCAKE COIL | |||||||||||||||||||

| 5 |  |

|

|

|

PANCAKE COIL | ||||||||||||||||||||||||

| 5,5 |  |

|

|

|

|

PANCAKE COIL | |||||||||||||||||||||||

| 6 |  |

|

|

|

|

|

PANCAKE COIL | ||||||||||||||||||||||

| 1,4 | 6,35 |  |

|

|

|

|

|

|

|

|

|

PANCAKE COIL | |||||||||||||||||

| 5/16 | 7,39 |  |

|

|

|

|

|

|

|

|

|

|

PANCAKE COIL | ||||||||||||||||

| 7,8 |  |

|

|

|

|

|

|

PANCAKE COIL | |||||||||||||||||||||

| 8 |  |

|

|

|

|

|

|

|

|

|

|

PANCAKE COIL | |||||||||||||||||

| 9 |  |

|

|

|

|

|

PANCAKE COIL | ||||||||||||||||||||||

| 3/8 | 9/52 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PANCAKE COIL | ||||||||||||

| 9,8 |  |

|

|

|

|

PANCAKE COIL | |||||||||||||||||||||||

| 10 |  |

|

|

|

|

|

|

|

PANCAKE COIL | ||||||||||||||||||||

| 12 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PANCAKE COIL | |||||||||||||

| 12,5 |  |

|

|

|

|

|

|

|

|

PANCAKE COIL | |||||||||||||||||||

| 1/2 | 12,7 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PANCAKE COIL | |||||||||||

| 13 |  |

|

|

|

|

|

|

|

|

|

|

|

PANCAKE COIL | ||||||||||||||||

| 13,5 |  |

|

|

|

|

|

|

|

|

|

PANCAKE COIL | ||||||||||||||||||

| 14 |  |

|

|

|

|

|

|

|

|

|

|

|

PANCAKE COIL | ||||||||||||||||

| 5/8 | 15,87 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

PANCAKE COIL | |||||||||||||

| 16 |  |

|

|

|

|

|

|

|

|

|

|

|

PANCAKE COIL | ||||||||||||||||

| 16,5 |  |

|

|

|

|

|

|

|

|

PANCAKE COIL | |||||||||||||||||||

| 18 |  |

|

|

|

|

|

|

|

|

|

|

|

PANCAKE COIL | ||||||||||||||||

| 3/4 | 19,05 |  |

|

|

|

|

|

|

|

|

|

|

|

|

PANCAKE COIL | ||||||||||||||

| 19,5 |  |

|

|

|

|

|

|

|

|

|

|

PANCAKE COIL | |||||||||||||||||

| 20 |  |

|

|

|

|

|

|

|

|

|

PANCAKE COIL | ||||||||||||||||||

| 22 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

PANCAKE COIL | ||||||||||||||

| 7/8 | 22,22 |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

PANCAKE COIL | |||||||||||||